Conclusion and Strategy Suggestions

A. Conclusion

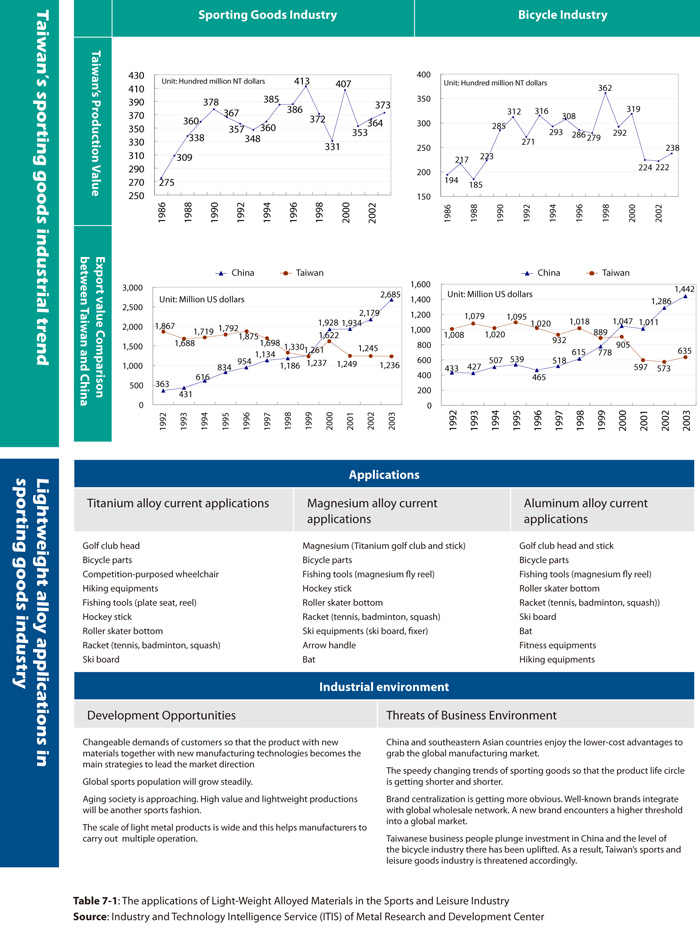

Viewing the history of Taiwan's sports and leisure industry over the past twenty years, Taiwan had excellent OEM (or ODM) skills and technologies to take the orders of international brands. Thus, the export value in 1996 of the sports and leisure industry could reach high up to 79.5 billion New Taiwan Dollars. Taiwan, during the period of time, was noted for Tennis Racket Kingdom and Bicycle Kingdom. Nevertheless, good times did not last forever. However, the rising China known for the global factory and the emigrating Taiwanese sports manufacturers have attributed to the overall declining production. If we compared the export value of sporting goods and bicycles over the past ten years across the strait, as indicated in Table 7-1, we can see that considerable changes happened greatly in the export value. When the export value of Taiwan gradually dropped, China showed a tremendous growth in its export value. It was from 2000 onwards that Taiwan's export values of sports and bicycle fell behind that of China. It is a clear trend that China keeps on growing and Taiwan faces the other way around.

From consumers" perspective of global sports and leisure goods, it is certain that they would like to have quality products so that they can enjoy doing the sports with secured feelings. Because of such a worldly recognition, the quality of sporting goods is better and better with modern technology. Particularly looking at the development of materials, from the past to the present, the popular materials changed from wood to steel, from steel to light-weight alloyed materials, carbon fiber materials composite materials, etc. Due to consumers" demands on light weight, strength, endurance of the sporting goods and the stricter security control, in the recent years there is a considerable room for the development of light-weight alloyed materials. Aluminum alloy has become the main material of many sports and leisure equipments. However, there is still a higher demand on the strength and corrosion resistance. Manufacturers have also started to apply Al-Sc alloy with less weight, higher strength and corrosion resistance. The applications of Al-Sc alloy in sports categories include baseball bats, bicycle frames, tent frames and hockey sticks, etc.

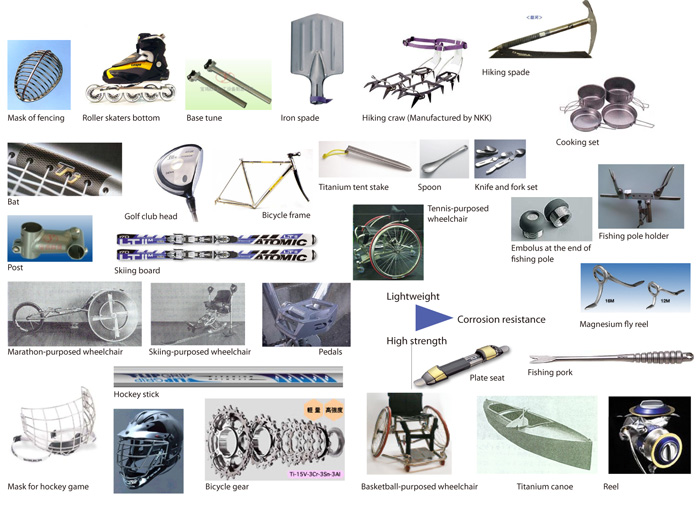

Viewing the development of Al-Sc alloy material, we know titanium is lightweight, high strength ratio, excellent corrosion resistance, not magnetic, not poisonous, high and low temperatures resistance, high anti-damping, low modulus of elasticity, low thermal conductivity, etc. Thus in the early times, it was mainly for military use and aerospace purposes. In the recent years, because the material melting and machining technologies has become mature, titanium has been used in the materials of sports and leisure equipments. In addition to the lightweight property, titanium has high strength ratio and corrosion resistance. They are the main reasons which manufacturers are motivated to use titanium alloyed materials for greater potential market. With the consideration of high strength ratio and lightweight properties, titanium-made golf club heads has been leading the global trend. Its production has been crowned as the champion among titanium-made sports and leisure equipments. Due to the use of titanium alloyed materials, the design of wooden club head has become thinner and larger. Apart from the golf club head, the parts of bicycles (frame, post, pedals, gear), competition-purposed wheelchair (for marathon, for tennis games, for basketball games and for skiing games), hiking equipments (hiking claw, hiking spade, iron spade, titanium tent spade, fire-making and cooking equipments, knifes, forks and spoons), hockey sticks, masks, roller skate bottom, etc. As shown in Table 7-2, because of the demand of high strength and lightweight, titanium alloyed materials are gradually applied. In addition to the mentioned properties of high strength and lightweight, titanium has such excellent corrosion resistance that guide of the fishing equipments, spool reel roller cover, plate seat, embolus at the end of a fishing pole, fishing pole holder, and others are all commercialized. Even we can find some of ship shield or cover is made of titanium alloyed materials.

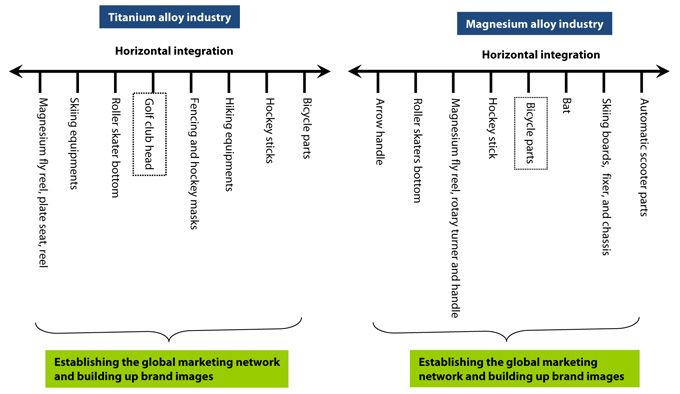

Table 7-2 Applications of Titanium Alloyed Materials in the Sports and Leisure Equipments

Source Industry and Technology Intelligence Service (ITIS) of Metal Research and Development Center

Magnesium alloy among light metals is the lightest metal. During the recent years, it has become one of the major applied materials in the sports and leisure industry. Especially among bike parts, the production of front fork, pedals, frame, post, breaking equipments, wheel, or gear plate are under the developing process of magnesium alloy. And most of front forks are already made of magnesium alloy among the sports and leisure equipments. In addition to bike parts, the recent applications of magnesium-made sports equipments include the bottom of roller skaters, hockey stick, baseball bat, arrow handle, golf ball, snow board, snow board bottom, belt hooks of ski boots, snow boots bindings, row paddle stick, automatic board frame and wheel, etc, as shown in Table 7-3. Though magnesium alloyed materials has lightweight property, it has not enough corrosion resistance. Domestic and foreign manufacturers actively improve the technology to better the surface so that among current fishing equipments, magnesium fly reel, rotary turner, and handles and many other fishing parts start to be produced with magnesium alloy.

Table 7-3 Magnesium alloy application in sports and leisure equipments

Source Industry and Technology Intelligence Service (ITIS) of Metal Research and Development Center

B. Suggestions on the Industrial Strategies of Development and Directions

Lightweight metals have gradually led the manufacturing trend of present metal-made products. Because Taiwan's government has been encouraging the metal related industries to upgrade to high value-added industries, lightweight metal industry is list as a significant item in the "High Value-Added Industries Plan" in the "Challenge 2008: National Development Plan." The aims are to construct a sound developing environment for domestic lightweight metal industries and provide consulting services to manufacturers to carry out the related innovation and R&D. Hopefully, the relevant development is taking its wing and solidifies Taiwan's position as the hub of lightweight alloy research and development.

However, with an overview of the lightweight-metal sports and leisure products, in the past the related manufacturers had played the role as professional OEM (or ODM) on the international arena. Now it is time to change this image. Particularly facing the low-price strategies of Chinese manufacturers and meanwhile, they are competent enough to handle orders from international brands. Taiwanese's industrial structure shall pace up to adjust industrial structures so as to meet the present market demands. Therefore, this report attempts to analyze what shall be the directions and strategies of Taiwan's lightweight alloy in the sports and leisure industry from market position, the developing direction, methods, speed and other perspectives, as shown in Table 7-4 for the references of the government, the academics, and industries, and the research institutes.

| Market position |

Building up brand names

Enhancing technological R&D resources |

| Development directions |

Horizontal integration: Broadening sports and leisure goods

Vertical integration: Establishing global market networking |

| Development methods |

Integrating cross-industry R&D resources: Enhancing domestic related technological R&D

Establishing the global R&D hub in Taiwan: Establishing global R&D bases

Market integration: Cooperating with other brands and carry out strategic alliance |

| Development speed |

Early stage of development: Apply alliance strategy to develop new technologies and products

Developing stage: Strengthening marketing so as to increase market share

Mature stage: Moving production lines to China and decrease the manufacturing cost |

| Market position |

Becoming the major manufacturing hub of global brands of sports and leisure goods

Becoming the technologic R&D hub of global sports and leisure goods |

Table 7-4: Strategy Suggestions to Expand the Development of Taiwan's Sports and Leisure Industry

Source: Industry and Technology Intelligence Service (ITIS) of Metal Research and Development Center

1. Market Position: Building up brand images so as to become a high quality and high value-added products hub

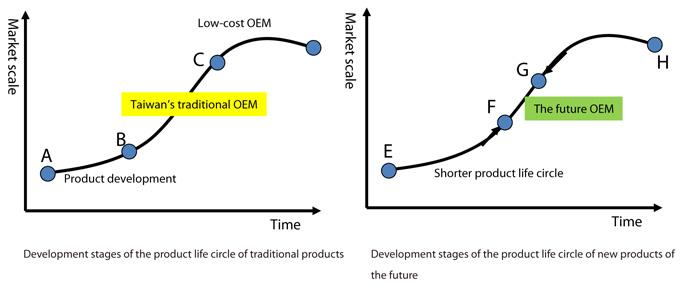

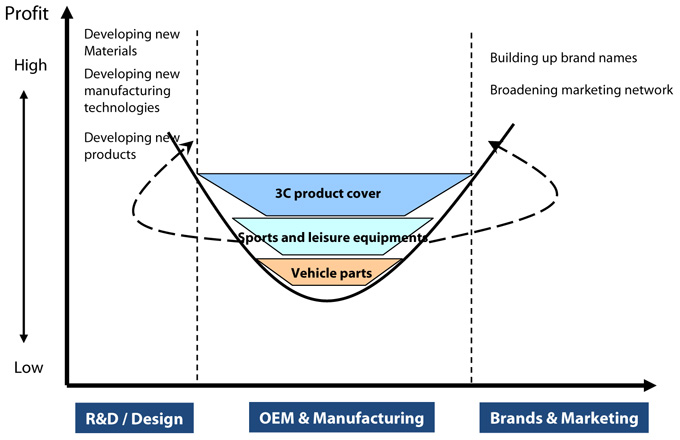

In the past, Taiwan based on outstanding manufacturing technologies was crowned as "Tennis Production Kingdom" and "Bicycle Production Kingdom." However, most of the manufacturers were focus on OEM (or ODM). Thus Taiwanese manufacturers mainly aimed to make profits from the process of B→C during product life circle, as shown in Table 7-5. Now China has more advantages of lower cost, Taiwanese manufacturers cannot reserve the profit from C→D but give it to the Chinese manufacturers. In the near future, new products come and go very quickly. The product life circle becomes shorter. Moreover, Chinese manufacturing capability is continuing to be better. As foreseen, the OEM profit of Taiwanese manufacturers is sharply cut in the coming future. The only left profit of the process F→G, on the right side of Table 7-5, according to the market position, our sports and leisure goods manufacturers are to develop towards the two sides of the smile curve, that is, one way is to enhance the material technology, manufacturing technology and the ability to develop new products, the other, establishing the global marketing network by building up a brand name. As indicated in Table 7-6, we see that expanding global marketing network and managing brand image as the most important steps. Based on Taiwan's outstanding OEM/ODM capabilities, accordingly enhancing manufacturing technologies shall be a better way for the industrial development. However, in the long term of industrial development, the survival of OEM/ODM manufacturers is still in the hand of international brands. It is factually advantageous to our industrial development in the long run. Thus, the report suggests that Taiwanese manufacturers shall build a global marketing network and solidify brand image, which could bring the long-term prosperity to the sports and leisure industry in Taiwan.

Table 7-5: The changing trends of life circle of the sports and leisure products

Source: The development and marketing of titanium-alloy golf club head (provided by Liu, Chung Yuan) / Collected by Industry and Technology Intelligence Service (ITIS) of Metal Research and Development Center

Table 7-6: Development directions of Taiwan's sports and leisure industry in the smile curve

Source: The development and marketing of titanium-alloy golf club head (provided by Liu, Chung Yuan) / Collected by Industry and Technology Intelligence Service (ITIS) of Metal Research and Development Center

2. Development direction: broadening the scale of applied product (horizontal development) and managing brand marketing (vertical expansion)

Supposed that enhancing R&D capability and building up a brand name are the better development strategy, the sports manufacturers could use Taiwan's lightweight alloy technology as the base and adopt the horizontal and vertical directions to upgrade the industry. On the horizontal development, the sporting goods manufacturers, apart from its continuation to enhance manufacturing technology and skills, can also use this material to other items of sports and leisure equipments or products. Take titanium as an example, the production line of titanium-made golf club head are established in Taiwan. If the lightweight alloy could be applied to bicycle parts (frame, post, pedals, gear), competition-purposed wheelchair (for marathon, for tennis games, for basketball games and for skiing games), hiking equipments (hiking claw, hiking spade, iron spade, titanium tent spade, fire-making and cooking equipments, knifes, forks and spoons), hockey sticks, masks, roller skate bottom, etc. even guide of the fishing equipments, magnesium fly reel, plate seat, embolus at the end of a fishing pole, fishing pole holder, and so on. As shown in Table 7-7, we are able to solidify Taiwan's manufacturing position in the global titanium alloy sports and leisure goods.

In additional to the horizontal development, the manufacturers also could use the current OEM/ODM ability to build a brand name and broaden marketing network. Meanwhile, they could also make good use of Taiwan's current sports brand images, such as the brands of the well-known fitness manufacturers, Johnson Health Tech. Co., Ltd., such as Johnson, Vision, Horizon, and Matrix, the brand, OKUMA, the reel manufacturer of Okuma Fishing Tackle Co., Ltd. and the bicycle brands, Giant and Merida, of Giant Manufacturing Co. Ltd. and Merida together with Taiwan's advanced lightweight alloy technology so as to explore more applications on sporting goods.

Table 7-7: Development directions of Taiwan's magnesium and titanium alloy sports and leisure goods industry

Source: The development and marketing of titanium-alloy golf club head (provided by Liu, Chung Yuan) / Collected by Industry and Technology Intelligence Service (ITIS) of Metal Research and Development Center

3. Developing methods: Integrating by cooperating with R&D institutes and establishing a global R&D hub in Taiwan and enhancing the marketing integration

In terms of the developing methods, because developing a new product is often in consideration with numerous manufacturing technologies, supposed that the resources of the domestic relevant institutes could be collected, the domestic manufacturers could be benefited to develop new products, particularly the sports and leisure equipments in face of the quickly changing customer demands. The life circle of sports products is getting shorter and shorter. Therefore, the product innovation needs to be quicker. Only with competent and sufficient technologies, the sporting goods manufacturers can catch up with the changing demands of customers. Apart from integrating the domestic R&D resources, for meeting the needs of the global marketing, the manufacturers shall setup a global R&D base so as to explore the sports and leisure equipments and products in need.

Additionally, in correspondence with the brands centralization of the global sports and leisure goods, the manufacturers can also make good use of the transitional period when international brands are discussing the integration. Through the relationship of allies to build up a network to become single-product specialized or professional suppliers, that is, the domestic manufacturers find ways to become the single-product supplier of the international brands. As to those domestic manufacturers who own brands, they could apply the strategic alliance or merger to expand their marketing network to cement their positions as international brands.

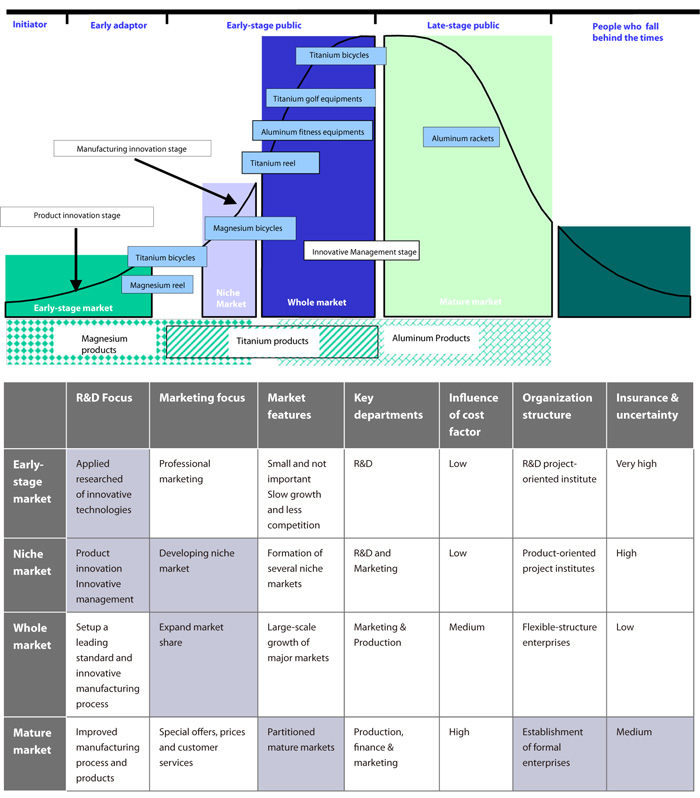

4. Developing speed: according to the product life circle, setup the goals of different stages

Looking at the development of the lightweight-alloyed sports and leisure products based on the product life circle, we can see that Al-Sc sports products are placed on the stages of "Whole Market" and "Mature Market." Take an example, the Al-Sc racket products are positioned on the stage of "Mature Market." Al-Sc bicycles, fitness equipments and reel are positioned on the stage of "Whole Market" as indicated in Table 7-8. Thus, in one way, Al-Sc sports and leisure equipments could be developed with implementing the "Whole Market" method so as to enlarge the market occupation ratio. On the other way, the domestic manufacturers can explore new products made of more outstanding materials, such as Al-Sc alloy. Otherwise, the manufacturers could also introduce more advanced manufacturing technologies (Tube Hydroforming) so as to promote products with more potential growth. On the whole, Al-Sc sports and leisure goods can be classified into the stage of "Management Innovation." Accordingly, how to low the cost and differentiate the production shall be the focuses of the strategic development. Taiwanese Al-Sc sports and leisure equipments manufacturers must actively carry out the operation model of "Take orders in Taiwan and Produce in China" and even use the new technology to develop new products and create product differentiation, for instance, Al-Sc Comfortable Bike produced by Giant Manufacturing Co. Ltd.

In the aspect of titanium alloy sports and leisure equipments, titanium-made golf club head has advanced itself from "Niche Market" to "Whole Market." Thus the current trading companies adopt the method of massive marketing and low production cost. As to titanium-made bicycles, because the manufacturing is not easy, titanium is mainly used for the production of high-end bicycle models. Undoubtedly, the product still remains on the stage of "Early Stage Market" and "Niche Market." From the perspective of technological innovation, Taiwan's titanium-made sporting goods have entered the stage of "Manufacturing Innovation" so the capability of mass production is the point of strategic development. With a view of the development direction, Taiwanese titanium-made sports and leisure goods manufacturers adopt the method of increasing production lines to uplift OEM/ODM manufacturing capability.

Table 7-8 : The different developing stages of the product life circle of Taiwan's lightweight alloy sports and leisure equipments

Source : Technological strategies (provided by Liu, Chung Yuan) / Collected by Industry and Technology Intelligence Service (ITIS) of

Metal Research and Development Center

As to the magnesium-made sports and leisure equipments, under the investment of R&D in magnesium-made bicycles over the past decade, now we can see considerable achievement that the said bicycles have been put into commercialized production. Supposed the product shall be positioned on the stage of "Niche Market." The direction of its future development shall be put on marketing part so as to enter the stage of "Whole Market." As to the part of magnesium-made reel cover, it is still on the stage of "Early Market." The R&D is still the main part of the product development. Overall, Taiwan's magnesium-made sports and leisure equipments are on the stage of "Product Innovation" of technological innovation. Production development is the major part of the strategic development, such as the cooperatively-developed bicycle parts made of magnesium. On this stage, it is more important to develop the products which meet market demands so as to enable the product to step into the stage of growth period.

5. Mark position: Establishing the global brand position and setup a R&D center in Taiwan

Supposed the above-mentioned strategic position and methods are adopted, Taiwan has very good advantages and position to establish a lightweight alloy R&D centre. Through the technology development, Taiwanese sports and leisure goods industry is able to build up a global brand name. Thus, our sports and leisure goods industry could possibly finds its way different from China's highly competitive low-priced manufacturers and creates a prosperous and promising future in the long run.

|