2010 Carbon Fiber Valley in Taiwan-Global financial tsunami has lead Taiwan's CFRP Industry upward

"Taiwan Carbon Fiber Composite Materials Research and Development Alliance" on September 18th, 2009, in the international conference hall of Taipei World Trade Centre established its General Assembly at this meeting. At this meeting, "Carbon Fiber Development Stability Plan" was officially stated and it will be carried out. The participants for the above-mentioned Alliance includes: the governmental units (Department of Industrial Technology, Ministry of Economy), the associations (Council for Industrial and Commercial Developments R.O.C., Value Management Institute in Taiwan, Taiwan Composites Association), the research institutions (China Productivity Centre, Chung Shan Institute of Science and Technology, Material Chemical Research Laboratories, Industrial Technology Research Institute, R.O.C.), the colleges (Department of Civil Engineering of Feng Chia University, Department of Civil Engineering of National Taipei University of Technology). At this meeting, the members of Carbon Fiber Development Stability Plan: Formosa Plastic Group, Formosa Taffeta Co., Ltd. gave talks, sharing experiences. Among them, Formosa Plastic Group gave a special report on "Carbon Fiber Current Development in China and the Future Direction of Formosa Plastic Group" winning the most attention and applause. Additionally, 31 enterprises in all took part in the R&D Alliance.

By the end of 2008, America's sub-mortgage crisis resulted in the global financial tsunami. Taiwan could not get rid of the impacts, neither. Among the most-hit industries, there is no doubt that "CFRP Industrial Application and Development in Taiwan" is still evaluated as a positive developing industry.

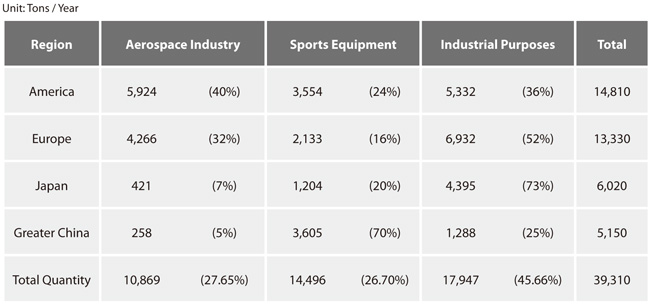

A. According to the statistic analysis reported by Crysel Operation Division of Formosa Plastic Group, the following table is the statistics of the three major global carbon fiber market demands of 2008 (the aerospace industry, sports equipment and industrial supplies).

From the above table, we see that CFRP application on sports equipment, Taiwan's manufacturing capability across Taiwan (Manufacturing) and China (mass production) has taken the leading position in the global market. Nevertheless, the ratio of sports equipment is only 26.70%. For the time being, despise the aerospace industry in Taiwan, CFRD application on industrial purposes shall be the most potential industry, 45.66%. Its scale is nearly double size of the sports equipment industry.

In the meantime, Taiwan is close Japan. Backed by CF Yarn Factories of Formosa Plastic Group, Taiwan shall develop its capabilities to take order from Japan regarding to CFRP application on industrial purposes. Taiwan's sports manufacturers already moved their factories to China; however, we shall maintain R&D experts and units and carry on the higher-level manufacturing sites.

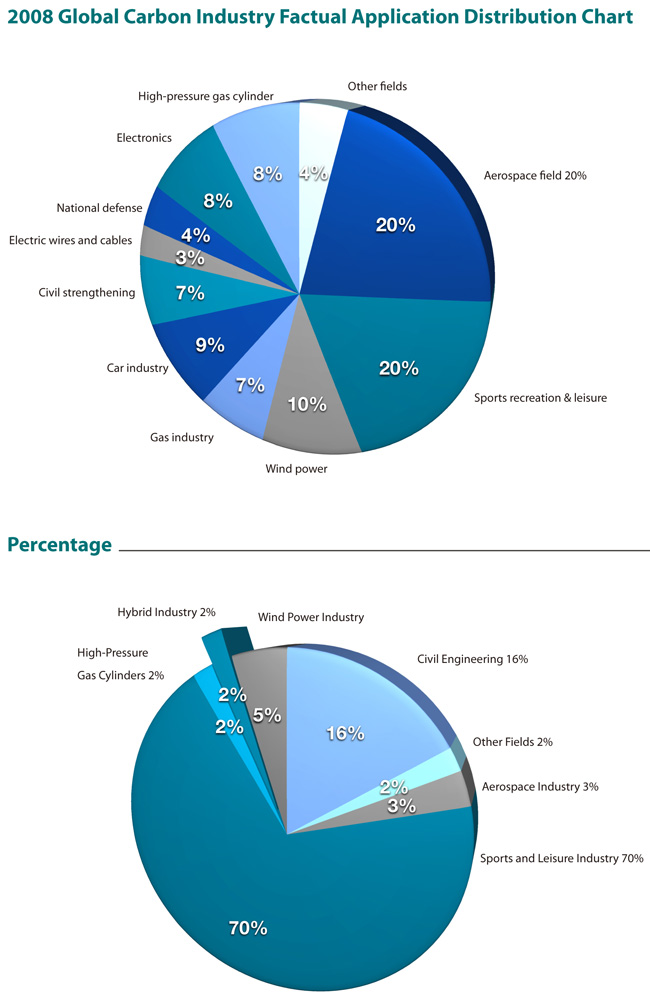

B. 2008 Global Carbon Fiber Industry Factual Application Distribution Chart

Comparing the above factual carbon fiber application chart with the global carbon fiber market demands table of 2008, we see that global CFRP applications on industrial purposes have been booming, particularly in the regions of Europe and Japan. The applications on sports equipment focus only in the region of Greater China. In contrast to the regions of Europe, America and Japan, Taiwan is on the right position to lead the production of carbon fiber applications on industrial purposes and upgrade the production of sports equipments.

C. 2008 China Carbon Fiber Industrial Applications Distribution Chart

From the above chart, it is obvious to see that China's development of CFRP industry mainly focuses on Taiwan's transferring sports equipments industry. In addition, the local energy industry must development itself with the market-adjourning production industry. Internationally, mainland China still lacks the skills and technology to produce high performance carbon fiber. Therefore, the status quo of Chinese carbon fiber manufacturers are confined to the price competition products. There is a long way for them to produce high performance or reliable CFRP products. When China took away massive orders of sports equipment which Taiwanese manufacturers are good at, Taiwanese surviving manufacturers have already upgrade to the high-value-added products (such as high-end bike parts) and the local industrial supplies (for example, the production-equipment parts of the TFT-LCD industry).

D. The present CFRP massive and high-value industrial items at the global market are listed as below:

A. CFRP Roller

Japan and Germany respectively have their leading position on the eastern and western world in the production of roller. Due to the fast operation of the printing machines, the original steel printing roller could not cope with fast printing and with changing printing mould. In the out-and-in operation of roller, CFRP roller have the features: high stiffness, light, decreasing moment of inertia (resistance resulted from roller rotation) and further decreasing quality defects. In the applications of huge-size monitors or materials of axle roller, the stretch of traditional metal materials is too large so that it causes distortion and the overall operation of machines overburdens motors. It not only wastes the electricity and causes lots of difficulties on the maintenance and replacing operation. CFRP industrial rollers offer excellent stiffness, less weight, energy saving. Certainly, there will be demands from the TFT-LCD industry for production equipment.

B. Civil Strengthening Construction Materials

The advantages of CFRP application on civil strengthening construction materials

1. Less weight

2. High Specific strength and stiffness

3. Corrosion resistance and fatigue resistance

4. Easy operation and short working period

5. Fewer impacts on the environment

6. Lower cost of construction cost

7. Prolong the life of the original structure and avoid demolition and re-construction

In the past, due to building regulations and rules, the government already sets considerable rules on carbon fiber strengthening work so that carbon fiber application of civil engineering strengthening has become a booming industry. Particularly in the earthquake-stricken areas and in the mainland China where reliable construction quality is not easy to find, great potential demands emerge in building strengthening construction market.

C. Carbon fiber electric wires and cables market

Comparing carbon fiber electric wires with steel-cored aluminum strand wires, because the electric impendence is lower, electricity transmission increases two times more. Besides, the longevity can be extended as well and meanwhile, the construction cost of high voltage circuit per unit distance can be decreased. According to the statistics, in the carbon fiber electricity board meeting reported by the end of 2008, in mainland China the total distance of power transmission circuit above 220KW has reached up to 268,400 kilometers. If supposed 10% of it needs to be changed annually, the demand of carbon fiber composite electric cables will be about 1,094 metric tons which about one fifth of Formosa Plastic Group's production capacity.

In mainland China, its government has set the carbon fiber development in the national development with supporting policies. The whole nation has exerted in the research and development of carbon fiber without calculating the return on investment rate first. Currently only confined by precursor skills and functions, China still cannot get mass production orders to enter the international market. Viewing this, the Chinese government guides the local carbon fiber manufacturers to sell products in the domestic market: Chinese products made of Chinese materials. The government encourages the industries, for instance the carbon fiber electric wires and cables manufacturers to produce products made in China, which is the priority partner. If the government cannot really help out the local carbon fiber manufacturers, they can attract those international manufacturers which like to introduce the production line (made in China).

D. Wind Power Turbine Blades Market

Wind power at present is regarded as the most marketable energy. The whole world has turned the eyes on its potential. The reserving capacity of China's wind power is high and the distribution is on a broad scale. The land-type wind power in China is about 253 million Kilowatts. No doubt, there is a great potential of development. Recognizing this value, the Chinese government has already targeted this energy. The wind-power development is fast now in China.

After 2006, the accumulated wind-power generators in China reach 2.6 million Kilowatts only after Europe, America and India. It has become one of the major wind-power countries. After 2007, China's wind power industry has had the dramatic growth. In 2008, China established new wind power generators which can reserve 719.02 Kilowatts. The growth rate of new wind power generators went high up to 108.4%. The reserved capacity of wind power reached 13,242.2 Kilowatts. Inner Mongolia, Shinjang, Liaoning, Shandong, Guangdong and other provinces has abundant wind power. Thus the wind power industry has a bright future for development. In 2009 the Chinese government views the overheated investment from the wind power industry. Therefore, the government announces that wind power investment is not one of the supporting-investment items so as to retain the high-waved investment.

E. The sharp turn of bike's international market

In 1999, Lance Armstrong, an American cyclist, won the championship of Le Tour de France. His arrival with the carbon-fiber bike was highly noted under the promotion of Trek, a famous bike brand of bike, plus the health issue of testicular cancer. When Armstrong reached the destination, he lifted up the carbon-fiber bike; the international press took pictures of it. Since then, the carbon fiber features were under spotlight. And soon it became the global fashion. In the following seven years of "Le Tour de France" carbon-fiber bikes were never out of topic. Having a carbon fiber bike has been a global fashion. It is a dream which people around the world share.

Over the hundred of years, bike parts were normally made of metals. Once the materials of bikes shift to carbon fiber, the bike manufactures in the west world had to face the fact: the bike orders shifted to the east world: Taiwanese carbon-fiber sports goods manufacturers, for example Tennes Racket, Golf shaft, etc. which have solid production technologies and the mass production of carbon fiber of Formosa Plastic Group. In addition, Japan had a long-term cooperation relationship with Taiwan. The global production of carbon fiber bikes almost relied on Taiwanese manufacturers. In the market, parts of a carbon-fiber bike are regarded as high end products. So the prices are high and the added values are high accordingly. The main reason is that the process of parts production takes long time. And as known, the carbon fiber quality is excellent. Moreover, there are fewer bike parts manufacturers and the production quantity is limited. But there is considerable room in the market for greater demands. So I predict the future of carbon fiber bikes is promising. As I see, European countries, America and Japan are not bike manufacturers. From manufacturing perspective, Taiwan has the great geographical opportunity to distribute the production across the strait. I believe that Taiwan can create a carbon fiber valley and the manufacturing industry will be booming in the run long.

Carbon fiber valley in Taiwan -

Manufacturing Powerhouse of the World

Since being as the Chairman of SAMPE / Taiwan, I have repeated this sentence as my propaganda. And I have promoted it as my belief. In the carbon fiber application industries, Taiwan started from OEM/ODM. From 1978, Taiwan introduced American production technologies of Tennes Racket, going through Golf Shaft, Bicycle Parts and other main CFRP sports goods' OEM/ODM. Taiwanese manufacturers have constructed a sound system of central-satellite factory. Again, it is an absolute advantage that Taiwanese manufacturers can distribute the productions of carbon fiber products across the strait. Plus, Formosa Plastic Group has established its carbon fiber business globally and provides sporting goods globally with CFRP applied products. Its invincible position around the world has definitely influence. In the future the industrial products can follow this carbon fiber trend and setup a carbon fiber valley in Taiwan and a manufacturing powerhouse of the world.

Conclusion:

Taiwan in 1978 introduced the production technologies of carbon-fiber tennis rackets and started the international manufacturing line. Later Taiwan had established its position as the sole CFRP sporting goods supplying country in the world.

Over the thirty years, Taiwan is proud of being a significant sporting goods manufacturing country. However, the value of its output, compared with other industries, has not been seriously cared by the enterprises or the government. In 1990s, Taiwan's traditional CFRP industries started to move offshore to mainland China. It was sad to learn that it was treated as a sunset industry in Taiwan.

From 2000 onwards, because of the global frenzy of carbon-fiber bikes, Taiwan's CFRP enterprises has packed up courage and investment. They enlarged manufacturing capacity from both Taiwan's and China's factories. Even after the global financial tsunami happened by the end of last year, the global market of carbon-fiber bike manufacturers were not affected at all. On the contrary, the global awareness "energy saving and carbon reduction" stimulates more purchase motivation and the bike market has been growing absolutely.

Besides, from the establishment of "Taiwan Carbon Fiber Composite Materials Research and Development Alliance" indicates that Taiwan's government recognizes its significance. The initiation of Carbon Fiber Development Stability Plan has crossed over to the field of civil engineering: Upgrade structure resistance to earthquakes. CFRP parts of the production equipments in the TFT-LCD industry previously relied on the Japanese original manufacturers. Nowadays, Taiwan already has production capacity and replaces the imported. The research and development of CFRP applied products was seen as the light in the carbon fiber valley to lead the sporting goods industry. Just a few miles away it would be anchoring in the mainland China. It is lucky in a way that while the global financial tsunami happened, the global promotion on bike for energy saving and for health, Taiwan noted as the kingdom of bike manufacturing catch the eyes of the world. In the times that bikes were mainly made of metals, Taiwan was simply the OEM/ODM main country. Now the main bike materials shift to carbon fiber. It is a way without return in the bike market. Taiwan-made carbon-fiber parts and whole bikes marketing will lead the global trend in the long run. When the economy across the strait is recovering after the global financial tsunami, several industries such as large-sized and one-touch TV monitor and electronic books are predicted as the new markets. Now monitor manufacturers have worked on larger sizes of TV monitor, e.g. G8.5 and G10. The new LCD investors in China are increasing rapidly. One after another state that the CFRP applied products in the TFT-LCD industry is the key of Taiwan to enter the CFRP applied industry. 2008 Global Financial Tsunami did not bring down the economy of Taiwan; in opposite, it will be the power to push Taiwan up on the international stage in the CFRP applied products industry. It is not exaggerating to make such a prediction. In 2020, we shall buildup the "Carbon Fiber Valley in Taiwan - Manufacturing Powerhouse of the World." The carbon-fiber sporting goods manufacturers shall have reflections and never miss out such a chance.

|